Process Air Heaters Summary

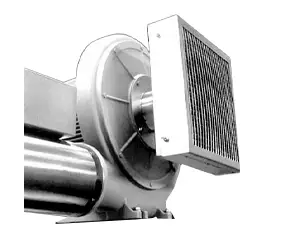

Process air heaters are designed for use with a suitable air source such as a centrifugal fan or side channel blower. They are designed to produce a continuous stream of clean, dry, hot, controlled air to the process.

PROCESS AIR HEATERS KEY FEATURES

• Class leading maximum outlet temperatures to 600 degrees C.

• Power loadings from 100 watt to 96kw.

• High grade 80/20 nickel-chrome elements

• 304 grade stainless steel bodies as a standard

• Can be built to specific end user/o.e.m specification

Options

• Single/three phase supply wound to specified supply voltage

• Un-insulated/Insulated heater bodies

• Terminal box or flying lead connections

• Inlet/outlet connection to customer requirements

• Thermocouple or PT100

• P.i.d. controller to specification

PEACE OF MIND

BESPOKE PROCESS AIR HEATER UNITS

Process Air Heaters by By Airtec. Airtec is unique in the fact that we can offer completely bespoke process air heaters tailored exactly to your requirements. We currently produce over 70 different body styles with options for flange or spigot connections flying lead or terminal box electrical connections. Many of these models have been customer specified to suit their individual requirements.

ASSISTANCE IN SELECTION

The outlet temperature is dependent upon the loading (power) of the heater and the volume of air passing through. It is possible to vary the outlet temperature by the use of air regulating valves/motor speed controllers (air volume control) or switchable elements/solid state P.I.D controllers (loading control)

APPLICATIONS

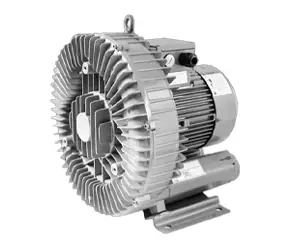

Looking For Air Knives Systems Or Blowers?

If you need a product to help with blowing away debris or blade-less cutting, see our Air Knives Systems page, alternatively we also offer a range of Side Channel Blowers, Centrifugal Blowers and High Speed Blowers.