Centrifugal Blowers deliver higher volumes of clean dry air at lower pressures when compared to side channel blowers and are ideal for lower velocity air knife applications and many other automation projects. Centrifugal Blowers are quiet and easy to maintain.

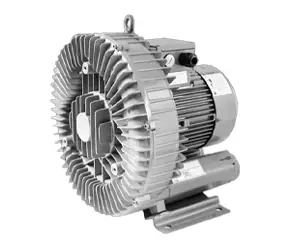

AIRTEC CENTRIFUGAL BLOWERS

Airtec Air Systems supply an unrivalled range of centrifugal blowers to a variety of industrial markets. This enables us to offer the widest choice of products to match your exact requirement. Standard features of the range include robust, corrosion resistant, epoxy resin coated cast aluminium housings suitable even for the most demanding applications. Stainless steel or corrosion resistant polypropylene housings are also available. Reliability is assured by the use of motors that are insulated to the highest class H specification. Energy efficient EFF1 and EPACT motors are also available on the entire range.

Call Us Today To Order A Centrifugal Blower: 01457 832 724

THE CENTRIFUGAL BLOWER PRINCIPLE

As the centrifugal blowers impeller starts to rotate, air is sucked into the inlet and directed in a centrifugal outward motion to the edge of the impeller and exits the outlet port. Relative to Side Channel Blowers, much higher volumes at lower pressures are achieved. Process can be connected to the outlet for blowing or to the inlet for vacuum.

Centrifugal Blowers: |

||

|

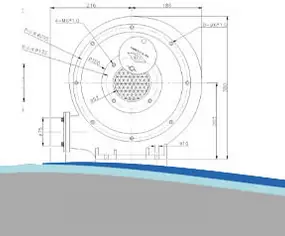

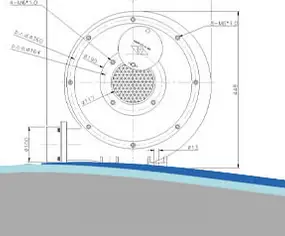

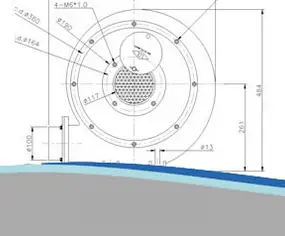

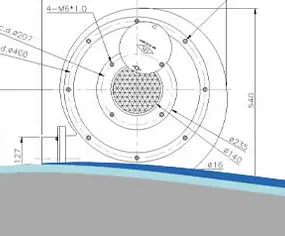

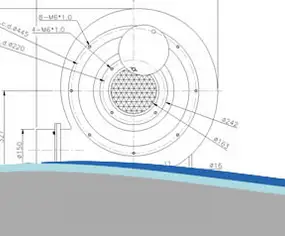

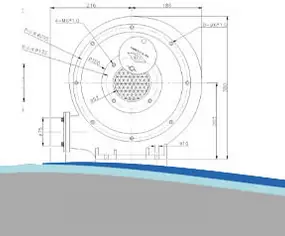

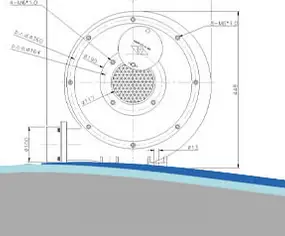

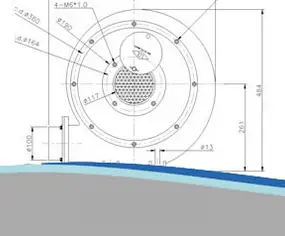

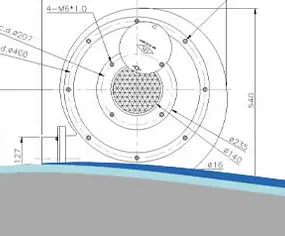

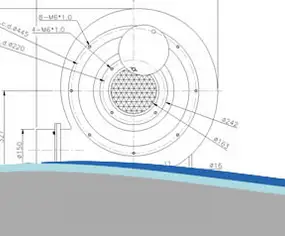

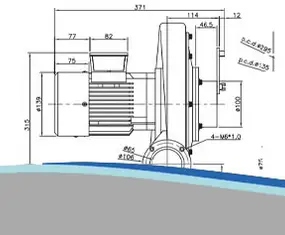

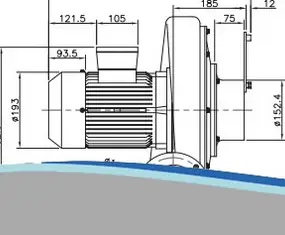

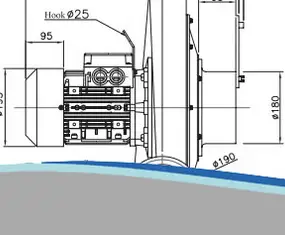

The TB 0400 PDF DRAWING | Download | Order Centrifugal Blower |

|

The TB 0750 PDF DRAWING | Download | Order Centrifugal Blower |

|

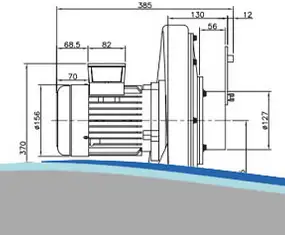

The TB 1500 PDF DRAWING | Download | Order Centrifugal Blower |

|

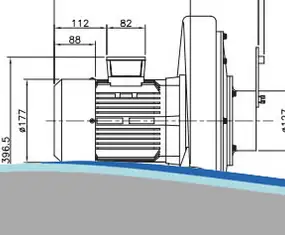

The TB 2200 PDF DRAWING | Download | Order Centrifugal Blower |

|

The TB 3700 PDF DRAWING | Download | Order Centrifugal Blower |

|

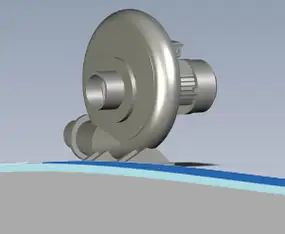

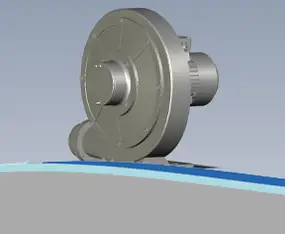

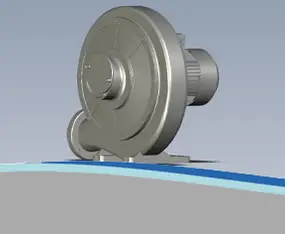

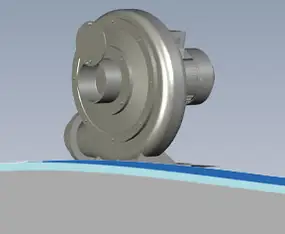

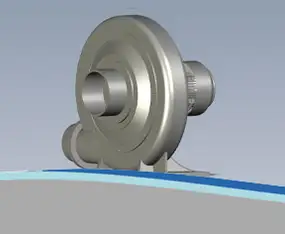

The TB 0400 3D DRAWING | Download | Order Centrifugal Blower |

|

The TB 0750 3D DRAWING | Download | Order Centrifugal Blower |

|

The TB 1500 3D DRAWING | Download | Order Centrifugal Blower |

|

The TB 3700 3D DRAWING | Download | Order Centrifugal Blower |

|

The TB 3700 3D DRAWING | Download | Order Centrifugal Blower |

|

The TB 0400 .DWG DRAWING | Download | Order Centrifugal Blower |

|

The TB 0750 .DWG DRAWING | Download | Order Centrifugal Blower |

|

The TB 1500 .DWG DRAWING | Download | Order Centrifugal Blower |

|

The TB 2200 .DWG DRAWING | Download | Order Centrifugal Blower |

|

The TB 3700 .DWG DRAWING | Download | Order Centrifugal Blower |

|

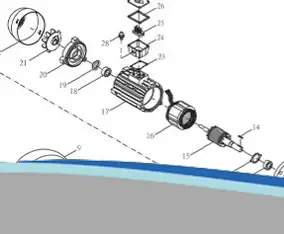

The TB EXPLODED DRAWING | Download |

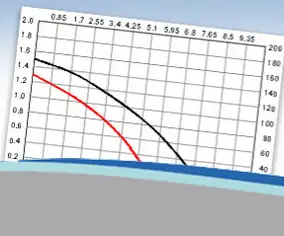

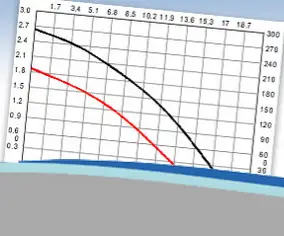

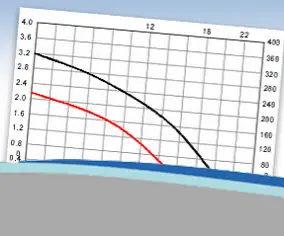

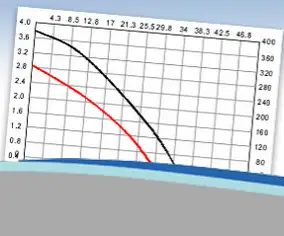

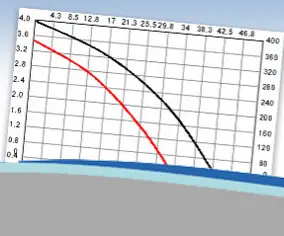

Centrifugal Blowers Performance Curves: |

||

|

TB 0400 3DATA SHEET | Download | Order Centrifugal Blower |

|

TTB 0750 DATA SHEET | Download | Order Centrifugal Blower |

|

TB 1500 DATA SHEETS | Download | Order Centrifugal Blower |

|

TB 2200 DATA SHEET | Download | Order Centrifugal Blower |

|

TB 3700 DATA SHEET | Download | Order Centrifugal Blower |

Centrifugal Blowers DATA SHEETS: |

||

|

TB 0400 3DATA SHEET | Download | Order Centrifugal Blower |

|

TTB 0750 DATA SHEET | Download | Order Centrifugal Blower |

|

TB 1500 DATA SHEETS | Download | Order Centrifugal Blower |

|

TB 2200 DATA SHEET | Download | Order Centrifugal Blower |

|

TB 3700 DATA SHEET | Download | Order Centrifugal Blower |

Centrifugal Blowers - What Are They And How Do They Work?

Centrifugal blowers are used in a variety of industrial applications where moderate volumes and medium pressures are required for a process. These blowers work by using centrifugal force to draw air into a spinning impeller, which then expels the air outwards. The result is a medium-pressure/high volume stream of air that can be used for tasks such as drying, cooling, and product conveying to name but a few. Centrifugal blowers come in many configurations with different impeller types, housings and motor options to give a range of performances across the whole spectrum of industry. It is crucial that the correct type is specified in order to maximise efficiency in a particular application.

Definition of Centrifugal Blowers

Centrifugal blowers, also referred to as centrifugal fans, are mechanical devices used for moving air or gas. They find applications in HVAC systems, manufacturing processes and wastewater treatment plants. A centrifugal blower consists of a rotating impeller which imparts velocity to the air or gas flow and an accompanying stationary housing which directs it in one direction.

Centrifugal Blowers And How They Work (Centrifugal Force)

Centrifugal blowers operate by using centrifugal force. As the impeller rotates at high speed, it creates a centrifugal force that propels air or gas from its centre to its outer edge. As it moves towards this edge, its velocity increases where it enters into the housing. The housing and impeller of the blower is designed in a specific way to convert the incoming velocity of the air or gas into pressure. As the air or gas enters the housing, it is directed towards the outlet or discharge port. The housing's design and impeller type determines the blower's pressure and flow characteristics, which can be tailored to specific applications. Centrifugal blowers can be single-stage or multi-stage, depending on the desired pressure and flow rate. In a single-stage blower, the air or gas is moved from the impeller to the discharge port in one step. In a multi-stage blower, the air or gas is passed through multiple impellers and housings, each stage increasing the pressure at a constant flow rate. Multi-stage blowers are used for high-pressure applications, such as in pneumatic conveying systems or industrial vacuum cleaners.

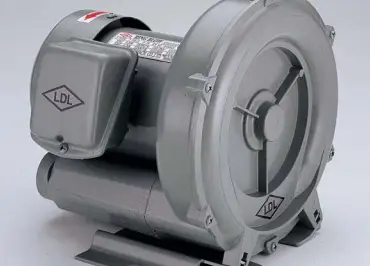

CENTRIFUGAL BLOWERS CONSTRUCTION

All centrifugal blowers are equipped with a low-noise, high-efficiency, class H insulated IP54 induction motors. Constructed from Cast aluminium alloy, all of Airtecs blowers are extremely robust, corrosion resistant and are suitable for the most demanding applications. They are continuously rated and suitable for ambient temperatures upto 40 deg C.

Advantages and Disadvantages of Centrifugal Blowers

Centrifugal blowers have several advantages over other types of fans and blowers. One of the main advantages is their high efficiency in converting mechanical energy into pressure. This means that they can generate high flow rates and moderate pressures with relatively low energy consumption. Additionally, centrifugal blowers can operate with higher inlet temperatures than other blower types, making them suitable for a wide range of industrial applications.

Another advantage of centrifugal blowers is their quiet operation. The design of the impeller and housing reduces noise and vibration, making them ideal for indoor environments where noise pollution is a concern.

Types of Centrifugal Blower Impeller (Forward-Curved, Backward-Inclined, Radial)

There are three main types of centrifugal blower impeller: forward-curved, backward-inclined, and radial. Each type has different performance characteristics and is suitable for specific applications.

- Forward-curved blowers are the most common type of centrifugal blower. Their high flow rate and low pressure characteristics make them perfect for applications requiring large volumes of air movement, such as HVAC systems or ventilation.

- Backward-inclined blowers are designed for high-pressure applications, such as industrial dust collection and pneumatic conveying systems. They have a curved blade design that allows them to handle higher pressure without stalling or surging.

- Radial blowers, also known as radial fans, have a straight blade design that allows them to generate high pressure at low flow rates. They are often used in industrial applications that require material handling applications.

CENTRIFUGAL BLOWERS APPLICATIONS

Some common applications include: Process cooling, air knife applications, fume/heat extraction, aeration, process drying.

CENTRIFUGAL BLOWERS ACCESSORIES

Centrifugal Blowers For Drying and Cooling of Products

One common application of centrifugal blowers in production lines is in the drying and cooling of products. These blowers are used to circulate hot or cold air around the products to speed up the drying or cooling process. The blower creates a high mass air flow, which helps to remove moisture from the products quickly and efficiently. This reduces the amount of time it takes to dry or cool the products, which in turn, increases the throughput of the conveyor belt system.

For example, in a food processing plant, air blowers are used to dry jars and containers before they are packaged. The centrifugal blower moves the hot air around the products to remove moisture quickly, which helps to maintain the quality of the products and reduces the risk of spoilage. Similarly, in a manufacturing plant, centrifugal blowers are used to cool down products after they have been processed. The blowers create a cool air flow that reduces the temperature of the products quickly and efficiently, which helps to increase the productivity of the plant.

Overall, the use of centrifugal blowers in production lines has revolutionized the way products are processed and transported. They have helped to increase the efficiency of the conveyor belt system and reduce the time it takes to process products. With their ability to dry and cool products quickly and efficiently, they have become an essential tool in the production process for many industries.

CENTRIFUGAL BLOWERS INSTALLATION

Supply requirements Our centrifugal blowers are available for a wide range of supply voltages:

• Single phase 110/240 Vac, 50/60Hz

• Three phase 208-255/360-440 Vac, 50/60Hz

These voltage ranges are accessible via simple link changes within the supply terminal connection box mounted on top of the blower.

Frequency invertors may be employed to vary the pressure/vacuum and volume flow rate to improve efficiency and fine tune the performance for a particular application. All units are continually rated and are suitable for supply frequencies in the range 40Hz (minimum) to 65Hz (maximum).

Using Centrifugal Blowers For Removing Debris, Dust, and Excess Material from Products

Centrifugal blowers are commonly used in production lines to remove debris, dust, and excess material from products. In many industries cleanliness is very important. Thus, centrifugal blowers are used to create a high-speed airflow to blow off any unwanted particles from the products. They can be used to clean items such as bottles, cans, and even food products, without causing any damage or altering the shape of the product. Used in conjunction with an air knife, they make an effective air delivery unit for a blow-off system.

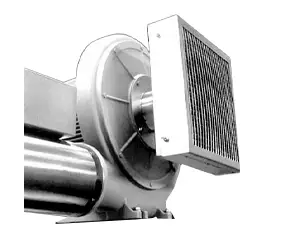

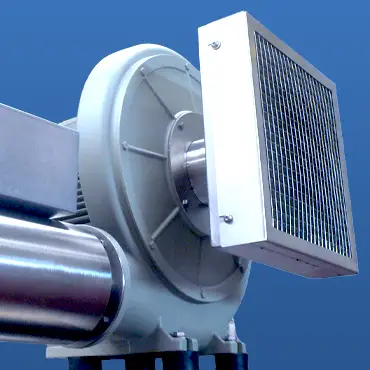

Boosting Airflow for Air Knives and Other Blow-Off Systems With A Centrifugal Blower

Centrifugal blowers are also used to boost airflow for air knives and other blow-off systems. Air knives are devices that use high-pressure airflows to remove debris and excess moisture from products. In many industries, such as automotive and electronics, air knives are used to remove debris and excess moisture from products before they are packaged or assembled. Centrifugal blowers can be used to provide the high-pressure airflows required to power the air knives and ensure that they are effective in removing debris and excess moisture from products.

Factors To Consider When Selecting a Centrifugal Blower For A Production Line

When it comes to selecting a centrifugal blower for a production line, there are several factors that one must consider. In this section, we will explore some of those factors.

Airflow and pressure requirements:

One of the primary considerations when selecting a centrifugal blower for a conveyor belt airknife application is the required airflow and pressure. This is because the amount of air required to move water, debri etc from product on the conveyor line can vary depending on the nature of the product, the size of the conveyor, and the distance the exit air needs to travel.

The airflow and pressure required will depend on the specific application, and it is essential to understand the requirements before selecting a centrifugal blower.

Efficiency and power consumption:

Another crucial factor to consider when selecting a centrifugal blower for a production line is efficiency and power consumption. The efficiency of a blower refers to how much air it can move per unit of energy input. The more efficient the blower, the less energy it will consume to provide the necessary airflow and pressure.

When selecting a blower it is essential to choose one that is energy-efficient to minimize operating costs. A variable frequency drive (VFD) can also help increase efficiency by allowing the blower to adjust its speed based on the required airflow and pressure.

Centrifugal Blowers - Noise Level

Centrifugal blowers are known for their ability to move large amounts of air with minimal noise. This is because they use a curved blade design that is optimized for efficiency and minimal turbulence. As a result, they generate less noise than other types of blowers or fans.

According to a study conducted by Industrial Noise Control Inc., centrifugal blowers produce noise levels ranging from 70 to 85 decibels (dB), depending on their design and size.

To put this into context, 70 dB is roughly equivalent to having a conversation in an isolated room, while 85 dB corresponds to heavy traffic noise.

Airtec Air Systems are waiting to help you with any enquiry Get in touch!

Regular Maintenance Procedures for Centrifugal Blowers

Centrifugal blowers require periodic maintenance to ensure they operate efficiently and safely. Proper maintenance can also extend the lifespan of your blower, saving you time and money in the long run. Let’s take a look at some of the regular maintenance procedures for centrifugal blowers.

Cleaning

One of the most important maintenance tasks for centrifugal blowers is cleaning. Dirt, dust, and debris can build up on the blades and housing of the blower, which can reduce its efficiency and increase the risk of damage or malfunction. Regular cleaning can help prevent these issues and ensure your blower operates at its best.

Inspection

Regular inspections are crucial for identifying any potential issues before they turn into major problems. During an inspection, you should look for signs of wear and tear, damage, and loose or broken parts. You should also check the airflow and pressure levels to ensure they are within the recommended range.

If you do notice any issues during your inspection, it’s important to address them as soon as possible. Ignoring or delaying repairs can lead to further damage and potentially dangerous situations.