Airknives and food production

Modern food production requires stringent quality control, increased output and reduced production costs. To help achieve all three of these requirements more industries are choosing to implement airknives as part of their product line.

Airknives are able to replace outdated and uneconomic machinery from food product lines, accelerate the production speed in the process. Here are the benefits airknives can bring to food production lines:

Save Energy

Compressed air usage for drying processes, especially in food production that contains several processing lines, can be expensive. By incorporating airknive drying products industries can reduce energy costs by up to 50%.

Flexibility

Modern production lines rarely produce just one single item. Lines need to be able to switch to other products, sizes or production speeds to reach demand; fortunately airknives are designed to suit a number of different processes meaning they can be used to produce a number of different food and beverage products.

Increased cleanliness

Airknives provide guaranteed performance for food blow off, ensuring that food lines remain clean and hygienic and companies are able to achieve their quality control targets.

Food Blow off

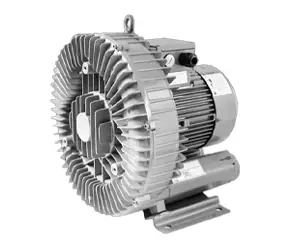

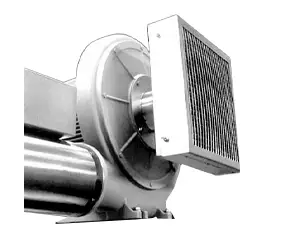

Food production systems need to be more compact, streamlined and quicker than ever before. In order to do this production lines need to implement airknives and sonic engineered blowers. They provide guaranteed improved performance, which helps lines run faster, occupy less space and be cleaner.

Container Drying

The drying of bottles, cans and other containers in a hygienic way requires certified air knife drying. In the past this was the job of industrial spray nozzles that were uneconomical and were very expensive to operate.

For more information on how airknives can benefit your food production, contact he team at Airtec today to speak with one of our experienced team members.