With oil lubricated machinery still being a popular addition to food processing facilities it is vitally important that they are well maintained and regularly serviced. Oil lubricant has the potential to contaminate food products and even affect the staff working within the production facility.

All machinery is installed with the appropriate technology to extract oil lubricant through filters to keep t away form food and to dispose of it in a safe way, but if these filters are not checked on a regular basis they can become oversaturated with oil causing particles to overflow. This can cause oil puddles to form underneath machinery and it can even bypass the filters all together. When oil droplets enter the air they can circulate and contaminate food or other products.

To make sure this never happens in your plant, make sure you follow this five-point checklist:

- Backup downstream oil filters should be installed to safeguard against your initial filtration system becoming blocked and starting to overflow. Any overflow will be caught by the backup and prevented from contaminating the environment.

- Regular and timely maintenance plans are your best way of avoiding minor equipment faults that risk oil discharging from exhaust ports and contaminating your processes. Regular checks are also proven to increase pump efficiency as well as the life expectancy.

- Food grade lubricants should always be used for food processing. Even with a rigid maintenance and servicing plan there is the potential for ace amounts of lubricants to me into contact with food. Food grade or incidental lubricants specifically designed to meet strict regulations should they come in to contact with food products.

- Always use genuine replacement parts to minimise future problems. Poorly fitted or poor quality replacement parts increase the likelihood of oil to be discharged rom the exhaust.

- Going oil free is a more readily available option thanks to modern technologies and processes. So, you could consider going oil free, which can cut down on costs over the long term but require a high initial investment, which means it may not be suitable for everyone.

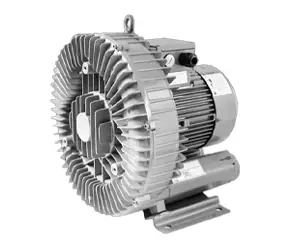

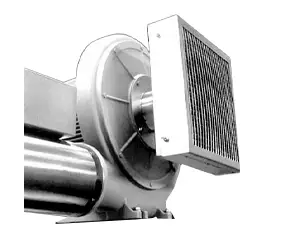

Ensure all your oil-lubricated machinery, from side channel blowers to centrifugal blowers are well maintained using this five point checklist.