It is no surprise that the UK has highly unpredictable weather especially when it comes to the British summer time; are we going to be facing cool days with a spattering of rain, or are we going to see months of blistering sunshine?

Whilst a scorching summer may be great for the general public to enjoy, hot weather spikes can cause havoc on industrial processes, especially when it comes to food production.

Excessive heat in a manufacturing warehouse brings up a myriad of problems; hot temperatures can greatly affect the quality of products as they are being produced and when they are being stored, it can also have negative effects on workers and their production levels.

Most industrial processes are designed to work to maximum efficiency under the correct temperature. These temperatures can differ depending on the product being produced. High heat can lead to production areas falling out of specifications, and potentially drastically reducing the output. This affects quotas and production targets for a number of industries all over the UK, so what can be done to combat the high heat of summer?

Ventilation is an important aspect of any production centre. The age-old solution of opening the doors and windows can sometimes be enough, but for industries that need a controlled environment, this simply won’t do. Dust, insects and other pollutants can easily contaminate a production line if the area isn’t kept sterilised through a secure facility.

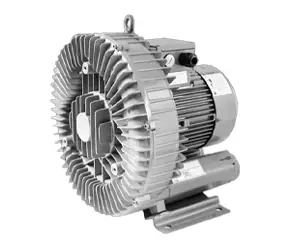

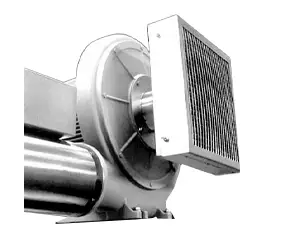

What could be the best solution, then, are plant-cooling options. Through mechanical cooling, whether it is of the entire facility and/or the production lines themselves, using cooling equipment such as air knives. Air knives are able to cool castings, extrusions, steel strip, light bulbs, ingot, metal extrusions and they can even be set to help cool products such as food, as they pass through separate pieces machinery.