Today’s industries are required to stick to strict production targets in order to meet demand, and one thing that can seriously disrupt their processes is an untimely breakdown with their equipment and machinery.

The only way to avoid these problems from occurring out of the blue is to regularly maintain and service all of your machinery, not just to prevent catastrophic failure but to ensure everything is working to its maximum potential.

These are some of the long-term benefits that you will receive if you instigate a machinery maintenance programme:

You can extend the lifespan of all of your machinery, ensuring you get the most out of it and to prevent your costly investments breaking down before their time. This also prevents the need for investing in new equipment at more regular intervals than is necessary.

Avoid unplanned downtime which can mean your company may miss quotas and fail to meet the demand of your product. Even small damages to machines can bring the whole process to a standstill, so whilst the repair job may not be that expensive, the time it takes to fix it can end up costing you exponentially more.

It also ensures that all machinery is working efficiently. Poorly maintained equipment often requires more energy to operate and will work slower and to a lesser quality than a well maintained piece of machinery that undergoes frequent checks and servicing.

By properly maintaining your equipment you can also increase the resale value if you want to invest in better equipment in the future using funds recuperated from your old machinery. Having a proper service record available means you will be able to get a much better price should you want to sell any machinery in the future.

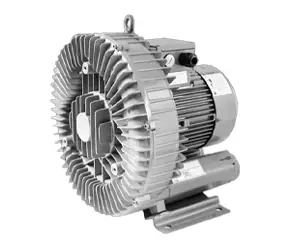

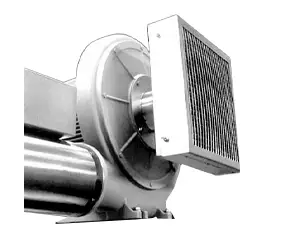

Always make sure you properly service and maintain all your Air Knives and other specialised equipment as these are considered big investments due to their large price tag and delicate workings.