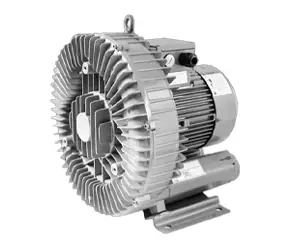

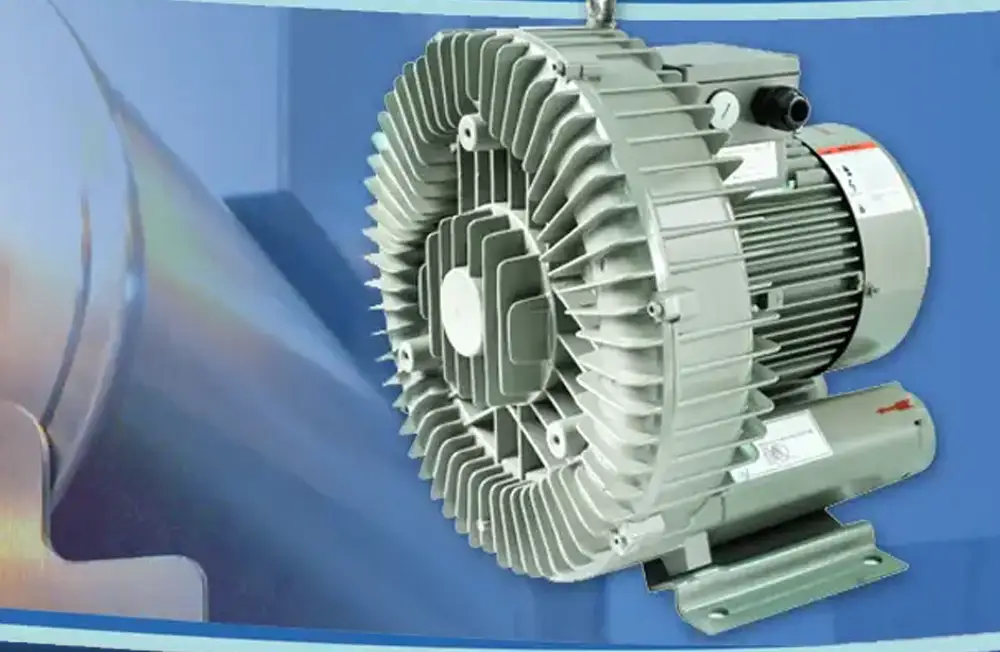

Side channel blowers are used in a large number of different production lines as they are able to provide solutions such as aeration of fluids, dry blowing, vacuum lifting, point suction, sealing air, blowing material and aeration of biological processes.

Although they are used by companies all over the UK to produce a wide variety of products few people are aware of how they actually work. Side channel blowers transport high-powered air and gases through narrow fitting pumps at high speeds.

They are able to do this via the rotating bladed fan close to a narrow fitting pump house. The turbulent stream intensifies the pressure in the channel creating a great differential pressure between the in- and outlet. As the built up pressure increases, it increases the build up on the drive. Because of this, side channel blowers are able to deal with pressure differences of up to 700mbar or 70kPa.

The drive itself is a asynchronous squirrel cage motor which is assembled with various other components of a side channel blower. There are also models available with a coupling or V-belt drive.

Side channel blowers are primarily used when vacuum clamping s required to old down large as where there is either potential for leakage or where the surface area is large enough to hold down a part.

With a higher flow rate than dry rotating vacuum pumps side channel blowers re suited to a number of industries that use full sheets on machine beds.

Visit Airtec website now for a wide range of side channel blowers of all shapes and sizes to suit a number of different industries.